Brand Name: YORK

Model Number: YLPA0115SE40XBA

Place of Origin: China (Mainland)

At YORK® by Johnson Controls, we offer the most efficient way to heat water for your residential and commercial needs with our reversible air to water heat pumps. A smart and simple alternative to boilers and water heaters, YLPA Air-to-Water Scroll Heat Pumps / Chillers have the capacity to provide both cooling and heating in an easy to install, centralized unit.

These air to water heat pumps are environmentally sustainable and deliver globally-certified energy efficiency and low sound levels suitable for almost any location.

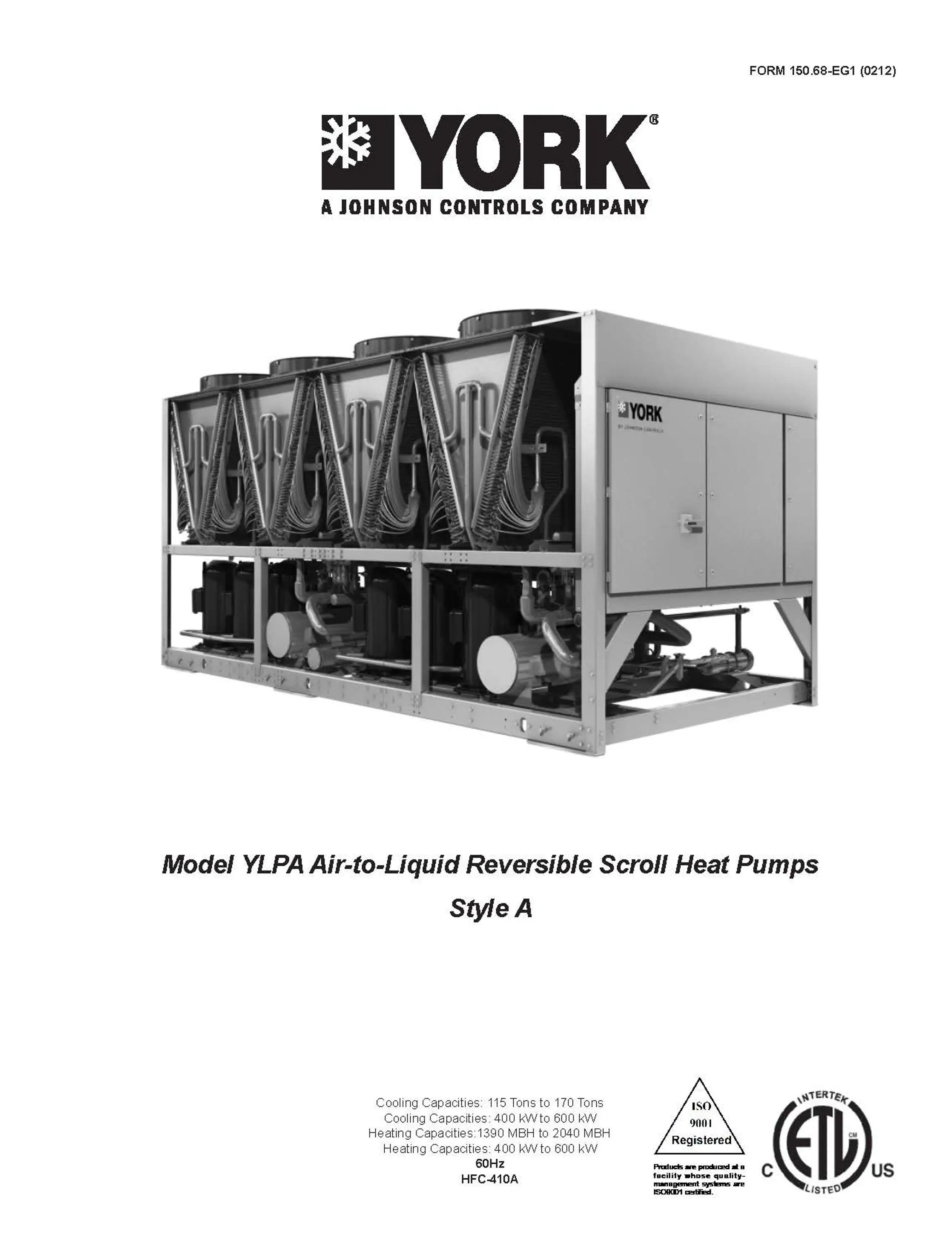

YLPA air-to-liquid reversible heat pumps are completely

factory assembled with all interconnecting refrigerant

piping and wiring ready for fi eld installation. The unit is

pressure tested, evacuated, and fully factory charged

with refrigerant R410A and oil in each of the independent

refrigerant circuits. After assembly, an operational test is

performed with water fl owing through the heat exchanger

to ensure that each refrigerant circuit operates correctly.

The unit structure is manufactured from heavy-gauge,

galvanised steel coated with baked-on powder paint

(Champagne (RAL 7006, Munsell No. 9.8YR4.36/1.2)).

YLPA heat pumps are designed in accordance with NFPA

70 (National Electric Code), ASHRAE/ANSI 15 Safety

code for mechanical refrigeration, ASME and rated in

accordance with ARI Standard 550/590.

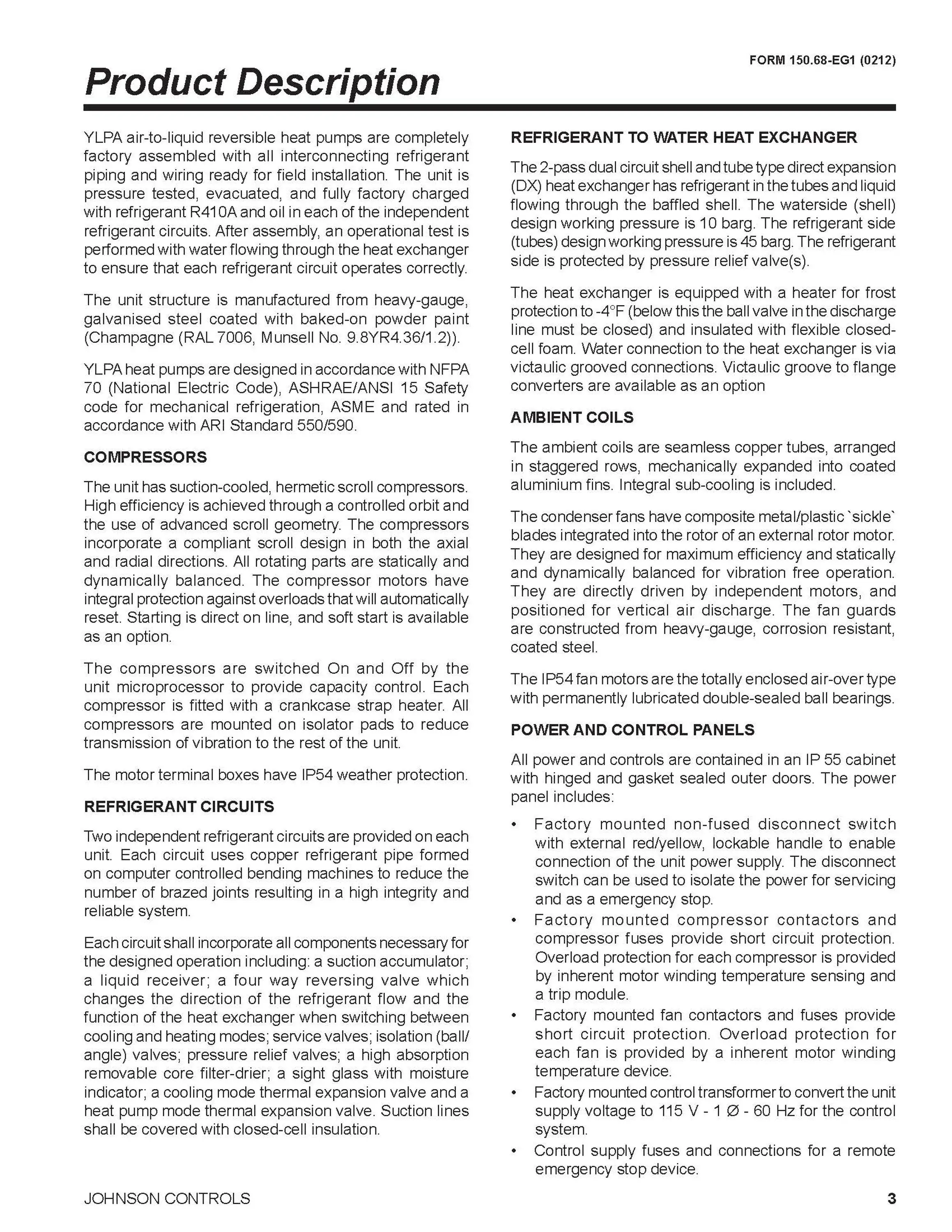

COMPRESSORS

The unit has suction-cooled, hermetic scroll compressors.

High effi ciency is achieved through a controlled orbit and

the use of advanced scroll geometry. The compressors

incorporate a compliant scroll design in both the axial

and radial directions. All rotating parts are statically and

dynamically balanced. The compressor motors have

integral protection against overloads that will automatically

reset. Starting is direct on line, and soft start is available

as an option.

The compressors are switched On and Off by the

unit microprocessor to provide capacity control. Each

compressor is fi tted with a crankcase strap heater. All

compressors are mounted on isolator pads to reduce

transmission of vibration to the rest of the unit.

The motor terminal boxes have IP54 weather protection.

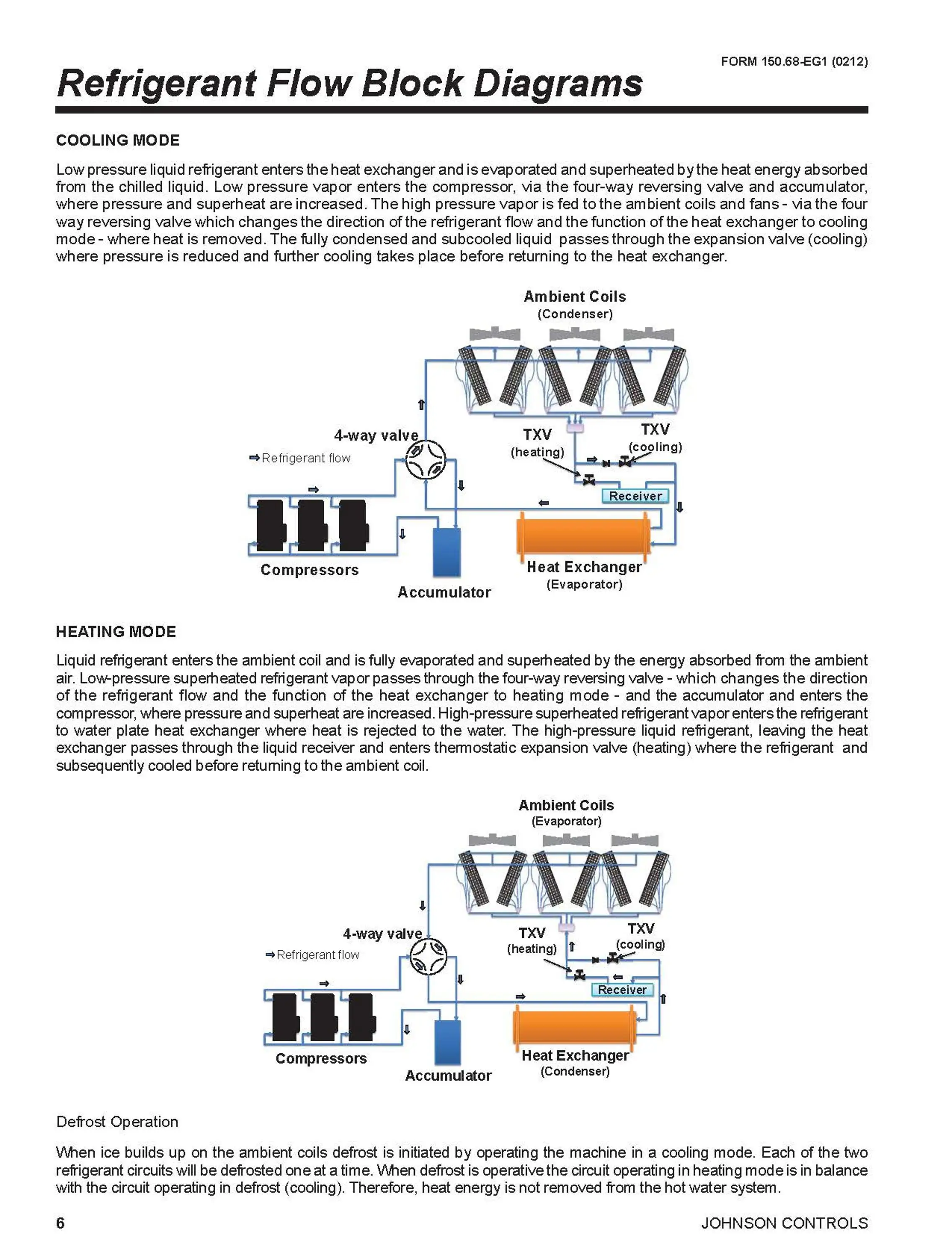

REFRIGERANT CIRCUITS

Two independent refrigerant circuits are provided on each

unit. Each circuit uses copper refrigerant pipe formed

on computer controlled bending machines to reduce the

number of brazed joints resulting in a high integrity and

reliable system.

Each circuit shall incorporate all components necessary for

the designed operation including: a suction accumulator;

a liquid receiver; a four way reversing valve which

changes the direction of the refrigerant fl ow and the

function of the heat exchanger when switching between

cooling and heating modes; service valves; isolation (ball/

angle) valves; pressure relief valves; a high absorption

removable core fi lter-drier; a sight glass with moisture

indicator; a cooling mode thermal expansion valve and a

heat pump mode thermal expansion valve. Suction lines

shall be covered with closed-cell insulation.

REFRIGERANT TO WATER HEAT EXCHANGER

The 2-pass dual circuit shell and tube type direct expansion

(DX) heat exchanger has refrigerant in the tubes and liquid

fl owing through the baffl ed shell. The waterside (shell)

design working pressure is 10 barg. The refrigerant side

(tubes) design working pressure is 45 barg. The refrigerant

side is protected by pressure relief valve(s).

The heat exchanger is equipped with a heater for frost

protection to -4°F (below this the ball valve in the discharge

line must be closed) and insulated with fl exible closedcell

foam. Water connection to the heat exchanger is via

victaulic grooved connections. Victaulic groove to fl ange

converters are available as an option

AMBIENT COILS

The ambient coils are seamless copper tubes, arranged

in staggered rows, mechanically expanded into coated

aluminium fi ns. Integral sub-cooling is included.

The condenser fans have composite metal/plastic `sickle`

blades integrated into the rotor of an external rotor motor.

They are designed for maximum effi ciency and statically

and dynamically balanced for vibration free operation.

They are directly driven by independent motors, and

positioned for vertical air discharge. The fan guards

are constructed from heavy-gauge, corrosion resistant,

coated steel.

The IP54 fan motors are the totally enclosed air-over type

with permanently lubricated double-sealed ball bearings.

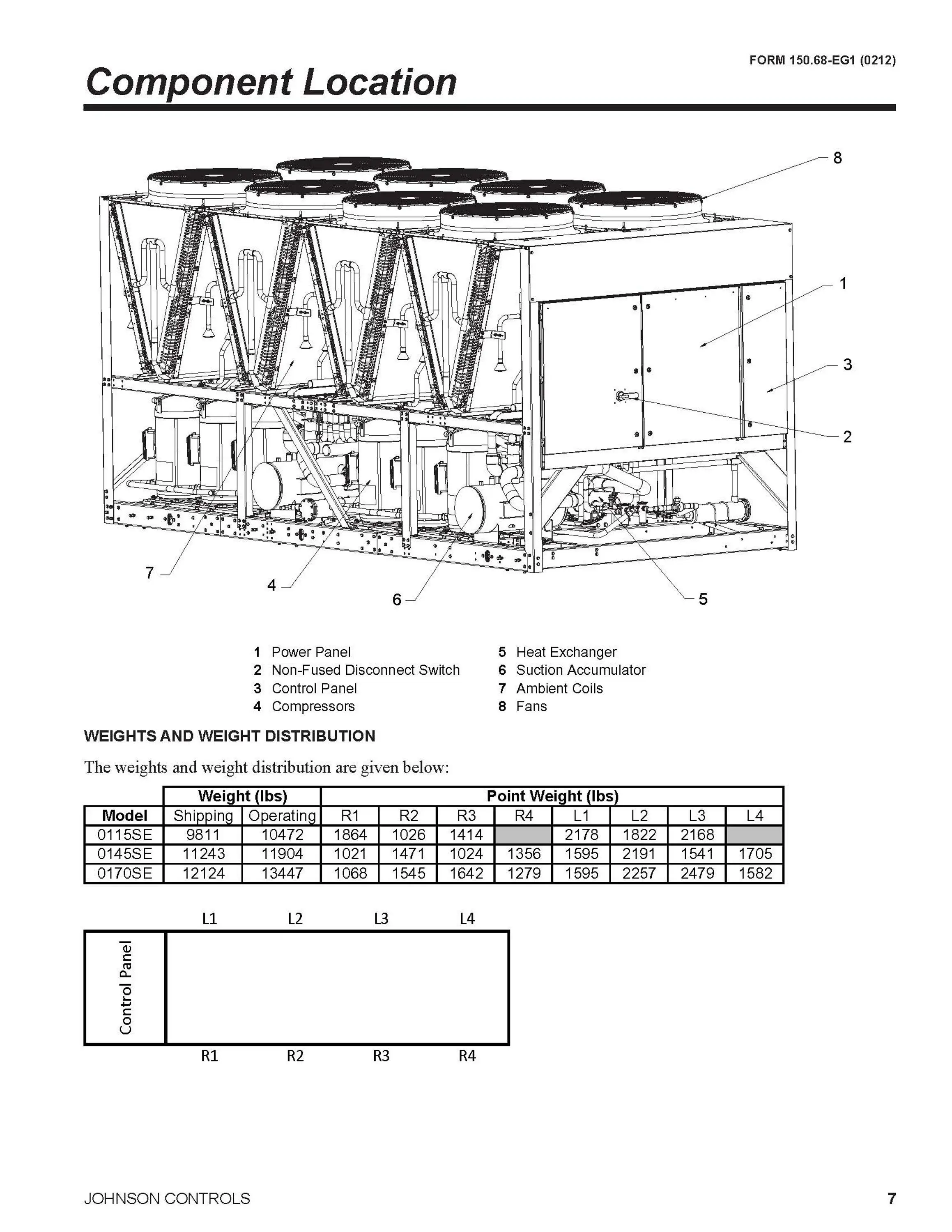

POWER AND CONTROL PANELS

All power and controls are contained in an IP 55 cabinet

with hinged and gasket sealed outer doors. The power

panel includes:

• Factory mounted non-fused disconnect switch

with external red/yellow, lockable handle to enable

connection of the unit power supply. The disconnect

switch can be used to isolate the power for servicing

and as a emergency stop.

• Factory mounted compressor contactors and

compressor fuses provide short circuit protection.

Overload protection for each compressor is provided

by inherent motor winding temperature sensing and

a trip module.

• Factory mounted fan contactors and fuses provide

short circuit protection. Overload protection for

each fan is provided by a inherent motor winding

temperature device.

• Factory mounted control transformer to convert the unit

supply voltage to 115 V - 1 Ø - 60 Hz for the control

system.

• Control supply fuses and connections for a remote

emergency stop device.

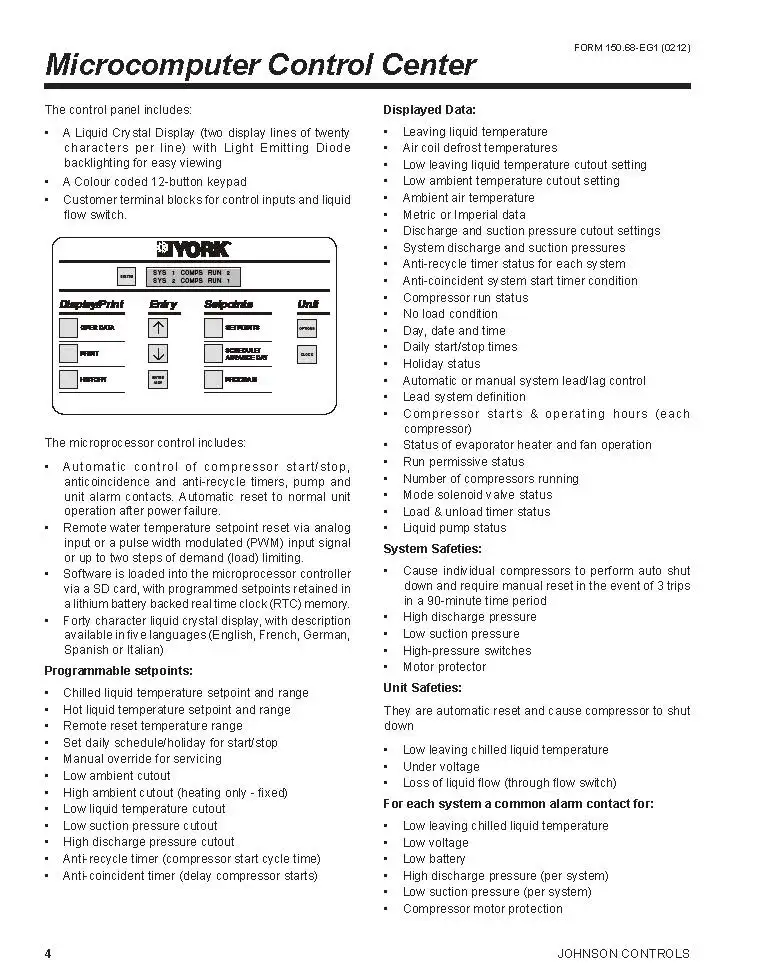

The control panel includes:

• A Liquid Crystal Display (two display lines of twenty

characters per line) with Light Emitting Diode

backlighting for easy viewing

• A Colour coded 12-button keypad

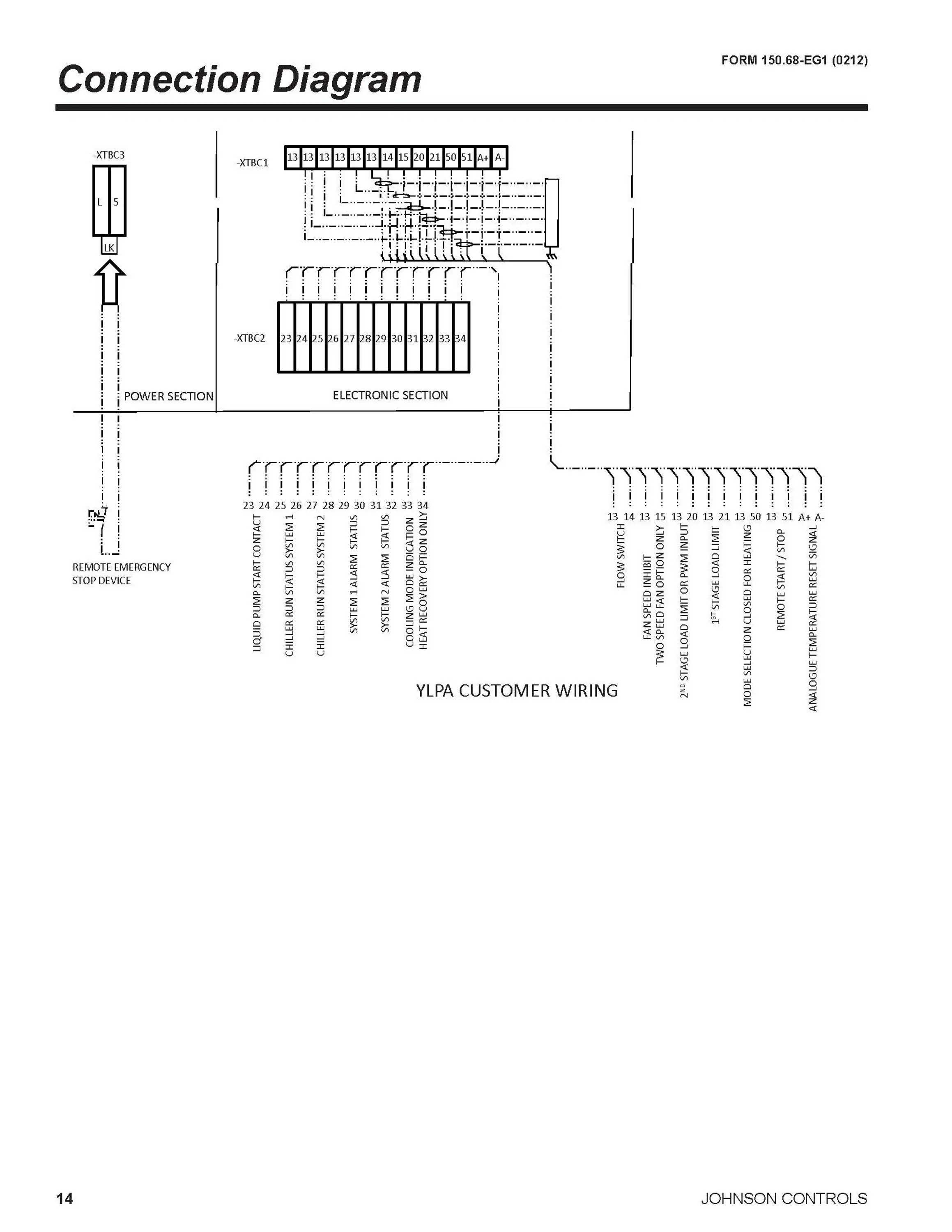

• Customer terminal blocks for control inputs and liquid

fl ow switch.

The microprocessor control includes:

• Automatic control of compressor start/stop,

anticoincidence and anti-recycle timers, pump and

unit alarm contacts. Automatic reset to normal unit

operation after power failure.

• Remote water temperature setpoint reset via analog

input or a pulse width modulated (PWM) input signal

or up to two steps of demand (load) limiting.

• Software is loaded into the microprocessor controller

via a SD card, with programmed setpoints retained in

a lithium battery backed real time clock (RTC) memory.

• Forty character liquid crystal display, with description

available in fi ve languages (English, French, German,

Spanish or Italian)

Programmable setpoints:

• Chilled liquid temperature setpoint and range

• Hot liquid temperature setpoint and range

• Remote reset temperature range

• Set daily schedule/holiday for start/stop

• Manual override for servicing

• Low ambient cutout

• High ambient cutout (heating only - fi xed)

• Low liquid temperature cutout

• Low suction pressure cutout

• High discharge pressure cutout

• Anti-recycle timer (compressor start cycle time)

• Anti-coincident timer (delay compressor starts)

Displayed Data:

• Leaving liquid temperature

• Air coil defrost temperatures

• Low leaving liquid temperature cutout setting

• Low ambient temperature cutout setting

• Ambient air temperature

• Metric or Imperial data

• Discharge and suction pressure cutout settings

• System discharge and suction pressures

• Anti-recycle timer status for each system

• Anti-coincident system start timer condition

• Compressor run status

• No load condition

• Day, date and time

• Daily start/stop times

• Holiday status

• Automatic or manual system lead/lag control

• Lead system defi nition

• Compressor starts & operating hours (each

compressor)

• Status of evaporator heater and fan operation

• Run permissive status

• Number of compressors running

• Mode solenoid valve status

• Load & unload timer status

• Liquid pump status

System Safeties:

• Cause individual compressors to perform auto shut

down and require manual reset in the event of 3 trips

in a 90-minute time period

• High discharge pressure

• Low suction pressure

• High-pressure switches

• Motor protector

Unit Safeties:

They are automatic reset and cause compressor to shut

down

• Low leaving chilled liquid temperature

• Under voltage

• Loss of liquid fl ow (through fl ow switch)

For each system a common alarm contact for:

• Low leaving chilled liquid temperature

• Low voltage

• Low battery

• High discharge pressure (per system)

• Low suction pressure (per system)

• Compressor motor protection

FLOW SWITCH - The fl ow switch or its equivalent must

be furnished with each unit. 150 psig (10.5 bar) DWP -

For standard units. Johnson Controls model F61MG-1C

Vapor-proof SPDT, NEMA 3R switch (150 PSIG [10.5

bar] DWP), -20°F to 250°F (-29°C to 121°C), with 1”

NPT connection for upright mounting in horizontal pipe.

(Field-mounted)

CHICAGO CODE RELIEF VALVES - Unit will be provided

with relief valves to meet Chicago code requirements.

(Factory-Mounted)

NEOPRENE PADS ISOLATORS - Recommended for

normal installations (Field mounted)

1” SPRING ISOLATORS - Level adjustable, spring and

cage type isolators for mounting under the unit base rails

(Field mounted).

2” SPRING ISOLATORS - Restrained Spring-Flex

Mountings incorporating a rugged welded steel housing

with vertical and horizontal limit stops. (Field mounted).

FLANGE KIT - Provides contractor with the couplings

best suited to tie into the chilled water piping. All fl anges

are PN10.

SINGLE-POINT SUPPLY TERMINAL BLOCK - Includes

enclosure, terminal-block and interconnecting wiring to

the compressors. Separate external protection must be

supplied, by others, in the incoming compressor-power

wiring. (Do not include this option if either the Single-Point

Non-Fused Disconnect Switch or Single-Point Circuit

Breaker options have been included.)

SINGLE-POINT CIRCUIT BREAKER - A unit mounted

circuit breaker with external, lockable handle (in

compliance with N.E.C. Article 440-14), can be supplied

to isolate the power voltage for servicing. (This option

includes the Single-Point Power connection.)

It’s well known that moving thermal energy from one substance to raise the temperature of another

is a more efficient form of heating than burning fuel. That’s why in residential and light commercial

space-heating applications, heat pumps are preferred over oil and gas furnaces and boilers. But the

benefit of heat pump efficiency is not limited to space heating. The same principle of efficiency can be

applied to heating water, which makes the YORK® YLPA Air-to-Liquid Heat Pump the smart alternative

to boilers and water heaters for commercial, institutional, and process applications.

As an air-to-liquid heat pump, the YLPA design takes thermal energy from the air and transfers it to the

liquid requiring heat. Using air as the heat source gives the YLPA heat pump the flexibility to be used

practically anywhere as a primary or a supplemental generator of hot liquids. And because it is reversible,

the YLPA heat pump can be operated in cooling mode providing a convenient heating and cooling

solution in one central unit.

When you think beyond the conventional boiler choice, you'll find the YLPA heat pump delivers benefits

that include:

• Globally certified energy efficiency in an extended operating envelope

• Low sound levels that are suitable for nearly any location

• Sustainability that makes your facility more environmentally friendly and helps achieve

LEED® certification

• Plug-and-play design that simplifies installation and commissioning

Although boilers and water heaters are typically the technology of choice for hydronic heating

and domestic hot water production, today’s high energy bills make it worthwhile to consider

more efficient ways to utilize the energy you’re buying.

The more efficient way to heat liquids is the YORK YLPA heat pump. That’s because thermal

efficiencies of commercial water heaters or boilers can range from 85% to 95%, which translates

into a coefficient of performance (COP) below 1.0.

In dedicated heat pump mode, however, the YLPA heat pump can produce hot water up to 130°F

at 3 times the COP of a boiler. The significant difference in COP means superior utilization of

energy input, making the YLPA heat pump a far more energy-efficient hot water generator — which

becomes even more attractive with up to 14.8 IPLV off-design efficiency in cooling mode.

To deliver a high COP, the YLPA heat pump employs an optimized defrost cycle using auto-adaptive

controls to run only as long as needed. Plus, enhanced liquid distribution through the coils in heating

mode, optimized coil-module design, and advanced fan control also boost COP.

With efficiency levels that exceed the ASHRAE 90.1 Standard and an extended operating envelope

down to 14°F, you can specify the YLPA heat pump with confidence — knowing it can create cold and

hot water at a lower cost in practically any location any time of the year.

The noise produced by outdoor mechanical equipment often draws a lot of attention.

That’s why more and more codes and ordinances adopted by states, cities, and townships

are including stringent decibel regulations to control sound emissions.

But with YORK YLPA heat pumps, we proudly point out how quietly they operate. YLPA heat pumps

are designed to help comply with sound requirements during the day, when background noise levels

often mask unit sound. And they make it easy to meet night-time requirements when sound-level

limits are typically an order of magnitude lower than day-time regulations.

Best of all, the YLPA design brings the advantage of quiet operation to heat pump duty.

Because heat pumps often operate with greater evaporator and condenser pressure differences

than chillers, the higher head pressure that results increases compressor workload and sound

output. But the YLPA heat pump is optimized to handle high head pressures and run as quietly

as a chiller. That means the YLPA heat pump doesn’t draw attention to itself.

Now you can get full credits for using a smarter water-heating solution.

That’s because the YLPA heat pump provides environmentally friendly benefits in two ways.

First, it reduces the direct effect of refrigerant interaction in the atmosphere by using HFC-410A

refrigerant, which has zero ozone-depletion potential and no phase-out date in accord with the

Montreal Protocol.

And second, the YLPA heat pump minimizes the indirect effect of utility CO2 emissions by using

less fossil fuel than boilers or water heaters, because it is always more energy efficient to transfer

heat than create it. The high efficiencies of heat pumps, when compared to boilers, help your LEED®

project qualify for Energy and Atmosphere credit 1 (EAc1).

When you add up both the direct and indirect benefits, the YLPA heat pump is the best heating

choice for the environment.

With today’s concerns about costs, you win points when you spend less on installation

and repairs.

That’s why the YLPA heat pump is designed to make installation fast and easy. The compact,

factory-tested YLPA unit minimizes the cost of rigging, pad size, and field testing.

And for power and control connectivity, the YLPA heat pump employs a “plug-and-play” design

using a single-point power connection. You stay in perfect control with continuous monitoring

via standard Metasys™ communications, as well as native BACnet,® Modbus,® N2 or optional

Lonworks® communications for virtually any BMS.

And to keep operating costs low, you can take advantage of the Johnson Controls global support,

parts, and service network, including optional Planned Service Agreements (PSA) coverage.

With over 15,000 technicians in over 150 countries, we’re the world’s largest HVAC and buildingservice

provider, bringing decades of chiller and heat pump experience to your door.

To learn more about why the YLPA heat pump is a smart solution for you, visit

johnsoncontrols.com/ylpa — or locate your nearest Johnson Controls branch office

at johnsoncontrols.com/locations.

York (Wuxi) air Conditioning and Refrigeration Co. Ltd, Located in Wuxi National High-tech Industrial Park, Jiangsu province, China. Covers an area of 60000 square meters, of which the heavy machine factory building takes up 14,000 square meters. At present, the company has about 500 staffs, in the field of large-size units. York Wuxi is the largest manufacturer in Asia –pacific region with an annual output of more than 3600 sets. Its products not only top on market share in China, but also see tremendous growth in export in recent years.

York Wuxi has six production lines in total, of which five are automated lines, including one air-cooled screw production line, one large-size water-cooled screw unit production line, one small-size water-cooled screw unit production line, and two centrifugal unit production line. All production line adapt the DFT technology, being the first in the industry. The entire work process is compact and rational. With the efficient management method (such as four-color light), these lines have become the most compact, most efficient and most advanced production line in the industry.

York Wuxi is equipped with globally advance equipment in every step of its production process, including:

Most advanced plasma digital cutter which can be used under water

Efficient digital plate bending machine with a roll length up to 4.8 meters

LINCO DC submerged arc welder imported from USA which is the most advanced equipment in the world.

Most advanced digital drill press in the industry.

Four large-sized chiller comprehensive performance test branches, (test capacity per set up to 2000 cold tons, for 10KV high voltage tests and frequency conversion tests), presenting the most advanced level in China.

YORK (CHINA) introduced the Performance Excellence Mode since the beginning of its operation. This mode adopted by most world-class enterprises focuses on the customers. It learns, meets and exceeds the customers’ needs and serves society through its human-oriented strategy and corporate culture. Based on the effective QEHS management system and advanced management tools (e.g. six-sigma).YORK (CHINA) consolidates its leading status in the industry.

1. YORK RESEARCH AND DEVELOPMENT

In December 2004, to provide high-quality and competitive air conditioning products and refrigeration equipments to the Asia-Pacific region and on the parts of the world, YORK set up the YORK Asia Pacific research and development center in

Wuxi.

The center has the most advanced software systems, highly qualified professionals, and various test equipments and systems. The air-cooled test bench, unique in China and the largest in the

Asia-Pacific region, which has complete spring base for the equipment vibration test, can lower the noise to 20db by means of muffle devices. It also can carry out the working environment temperature simulation test by changing the indoor temperature via air conditioning and refrigeration system.